JWS Ticketing and Automation Solutions Keep Trucks Moving at State-of-the-Art Cement Terminal.

By Mark S. Kuhar

When Pan Pacific Cement contacted Command Alkon for a ticketing solution at a new Cement Terminal in the Port of Sacramento, it became obvious that the JWS Apex system was an ideal fit.

Pan Pacific Cement, a subsidiary of the Caillier Investment Group, was looking for a system that could meet the following requirements:

- Expedite the ticketing process for a high volume of truck traffic at a facility with an estimated capacity of 1.2 million tpy.

- Interface to a third-party PLC loadout system.

- Interface to an existing COMMANDseries system for Billing and Enterprise Content Management.

- Deliver and implement on time. The system had to be ready to go when the first ship arrived.

A leading supplier of ticketing and automation solutions for the bulk materials industry, JWS could leverage its experience with the largest cement suppliers in North America to help design a solution that would meet all of the requirements for Pan Pacific Cement.

The final result would be a cement loadout facility with a typical load time of three minutes, far exceeding the industry average.

Site Survey and Project Planning

|

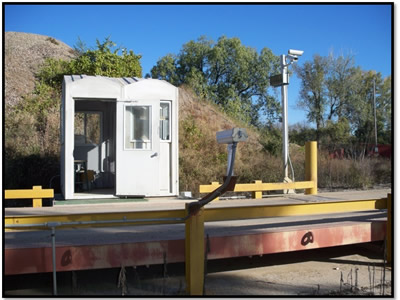

| Pan Pacific Cement’s new terminal at the Port of Sacramento. |

|

| Each loadout lane includes an RFID Terminal, Remote Printer and Integrated Video Capture. |

The first step was a site survey while the terminal was still under construction to understand the physical layout and to clarify the specific technical requirements. The terminal would have three loadout lanes, each with a two-section truck scale and two surge hoppers overhead to allow for simultaneous loading of front and back trailers. They wanted to be able to operate all three lanes efficiently with a single loadout operator.

After reviewing the site, JWS recommended the use of RFID readers for quick identification of trucks when they arrive and outdoor printers mounted at cab height, eliminating any need for drivers to get out of their vehicles – ensuring both efficiency and safety for the drivers.

JWS worked with Pan Pacific on appropriate positioning of the hardware so it could be incorporated into their existing construction plans. Matt Fox, the project manager for JWS, maintained constant contact with Pan Pacific Cement and the third-party PLC provider to ensure that everything was on schedule and that all of the infrastructure at Pan Pacific Cement’s new terminal would be in place when the technician arrived on site for installation and setup of the Apex system.

Technology Overview

The implementation for the Pan Pacific Cement terminal employed the following software and hardware solutions from JWS.

- Apex Ticketing – At the core of the system is the Apex ticketing software, providing an intuitive Windows user interface for data management and ticket printing at the site.

- Auto ID – This module interfaces with the core ticketing application to allow the use of RFID readers and remote user input devices to automate the ticketing process.

- Third-Party Controls Interface – Apex systems can communicate with a third-party PLC using a standard OPC (OLE for Process Control) interface. This allows the Apex application to provide information such as Target Weights, Bin ID, etc. to the loadout control system and to monitor status conditions.

- Remote Ticket Printing – An environmental enclosure, designed specifically for outdoor printing in conditions found in the bulk materials industry, houses an industrial printer for rapid delivery of tickets to the driver.

- Scale Watcher – Integrated video capture provides a still image of truck license and side door view for every ticket generated. These images are stored with the ticket, eliminating the need for driver signatures. Each loadout lane includes an RFID Terminal, Remote Printer and Integrated Video Capture.

Process Flow

|

| An environmental enclosure, designed specifically for outdoor printing in conditions found in the bulk materials industry, houses an industrial printer for rapid delivery of tickets. |

|

| Loadout operator manages all three lanes. |

Each vehicle is issued a handheld RFID badge. The Apex system stores all of the information required to load each vehicle, including configuration (single or double trailer), target weights for each trailer, maximum GVW, billing information, etc.

When a truck pulls into a loadout lane, the driver presents the badge to the RFID terminal mounted at cab height. The driver will confirm his assignment on the terminal, or contact the loadout operator if his assignment information needs to change. Once confirmed, Apex will capture the tare weight and communicate the lane ID and target weights for this vehicle to the loadout PLC.

The operator will lower the spouts and initiate the loading. The scale configuration allows the PLC to load a front and back trailer simultaneously with independent target weights. Once the loading is complete and the spouts have been raised, the PLC will set the appropriate status and the Apex application will capture the final gross weight and print a delivery ticket at the appropriate remote printer.

At the time the ticket is printed, the Scale Watcher module will store the video capture from two cameras, with an overlay of key ticket data values, as a pdf image that is indexed by ticket number for easy retrieval in the Apex application.

An additional image of the printed ticket is stored in the ECM (Enterprise Content Management) system. From beginning to end, including the cement loading time, the entire process is completed in as little as three minutes.

Conclusion

The Pan Pacific Cement terminal is an excellent example of how the combined technology and industry experience of Command Alkon and JWS can be counted on to provide best of class solutions for the construction materials industry.

The customer was able to implement a state-of-the-art Apex bulk material ti cketing application, including RFID and video capture integration, while continuing to utilize the Command Alkon Billing and ECM systems already in use within their sister companies.

This terminal will be an important link to meeting the needs of concrete producers in the northern California market, and Command Alkon is proud to be able to do its part to help keep Pan Pacific Cement’s customers trucks moving.

Information for this article courtesy of Command Alkon.